- 3D printed parts in as fast as 2 days

- Various materials and surface treatments are available

- Machining-CNC provides technical support and design guidance as well as improvement suggestions

- ISO 9001:2015 Certified Factory

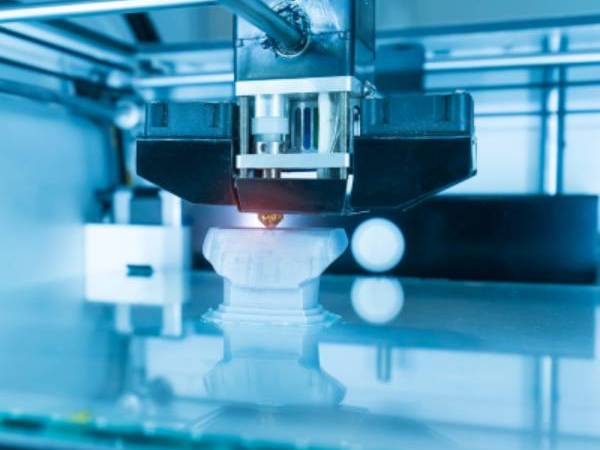

Our 3D Printing Services

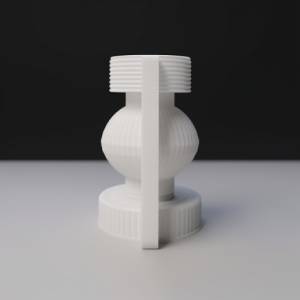

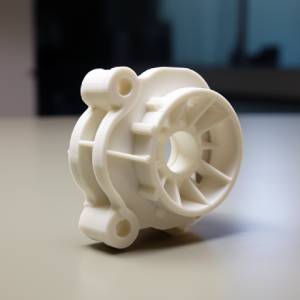

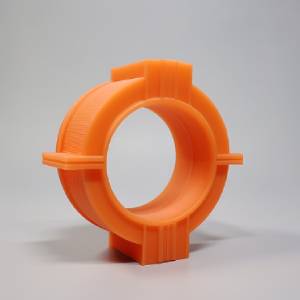

Our online 3D printer service uses six 3D print technologies to turn your 3D models into plastic, metal, and elastomeric products. Our unmatched capacity to deliver parts in days is due to our 20 3D printers. Our wide selection of materials is complemented by a range of post-processing techniques to improve cosmetics and mechanical properties.

|

| Stereolithography |

| Stereolithography (SLA) is an additive manufacturing technology that uses a UV laser to cure liquid resin layer by layer, creating 3D objects. |

|

| Selective Laser Sintering |

| Selective Laser Sintering (SLS) is a 3D printing method using a laser to fuse powdered materials for creating objects, often with nylon or polymers. |

|

| What’s 3D printing? |

| 3D printing is like having an amazing machine that can create real objects. Instead of using ink on paper, it uses special materials like plastic or metal. Here's how it works: First, you create a design on your computer using special software or find pre-made designs online. You then send the design to the 3D printer, which follows the instructions and begins building the object layer by layer. Think of it like building something out of Legos, but in a very tiny and precise way. A 3D printer adds layers of material layer by layer until the entire object is complete. Simply put, 3D printing is a method of making real objects by using special machines to add layers of material together based on computer designs. |

|

| Our 3D Printing Processes |

| Machining-CNC offers a variety of top-quality 3D printing (additive manufacturing) services, such as FDM, SLA and SLS. We provide high-quality processes to produce high-precision and customized 3D printed components at lower costs that are delivered on time and in a timely manner from prototyping to production components. This permits 3D printing of both plastics and metals, and also offers alternatives for prototyping as well as production. |

Advantages of 3D Printing in Machining-CNC

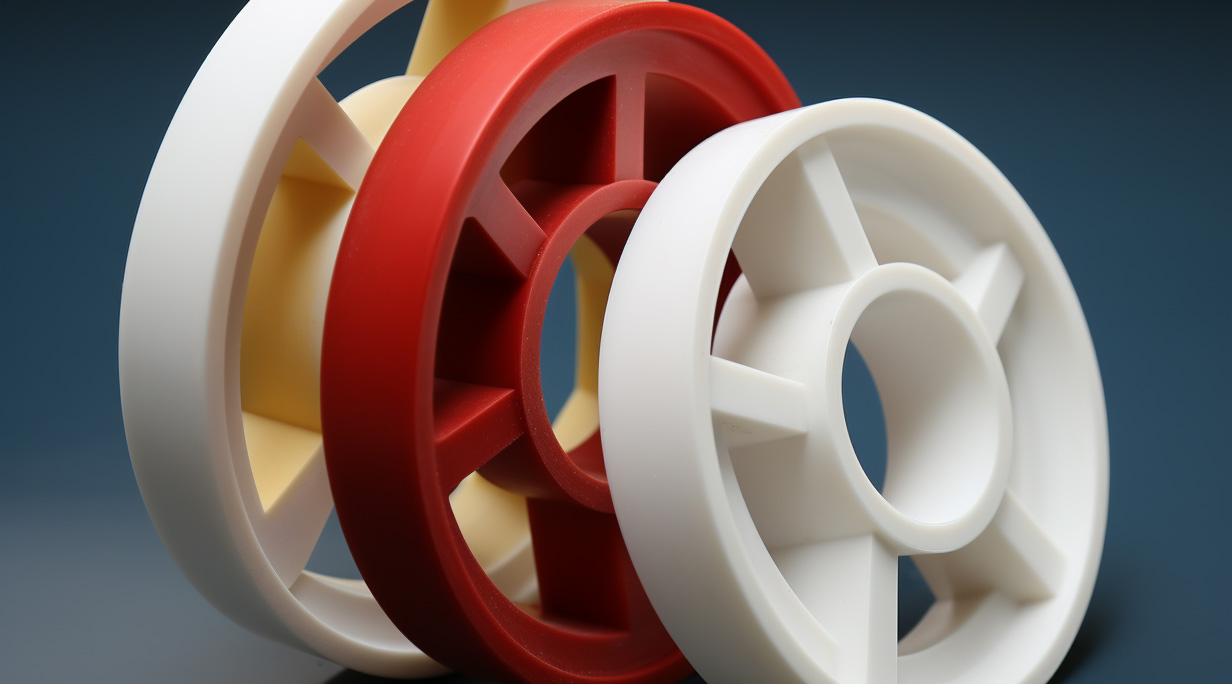

Materials

|

|

| PLA | |

| This material exhibits excellent rigidity, fine precision, and competitive pricing. It is an environmentally-friendly thermoplastic that possesses favorable physical attributes, as well as strength and flexibility. It offers accuracy up to 0.15mm, alongside a subtle striped pattern. |

|

|

| ABS | |

| This plastic is widely available and possesses advantageous mechanical and thermal characteristics. It is a popular thermoplastic choice due to its impressive impact resistance and reduced level of intricate features. |

|

|

| Nylon | |

| This material displays notable resistance to impact, as well as impressive strength and durability. It possesses a high level of hardness and exceptional dimensional stability, with a maximum heat resistance temperature ranging from 140 to 160 °C. Furthermore, it is classified as a thermoplastic and boasts outstanding mechanical properties, along with high resistance to chemicals and abrasion. Notably, it also features a fine powder finish. |

|

|

| Aluminum Alloy | |

| Aluminum alloys have the capability to be utilized in the processes of 3D printing. Diverse techniques are available for 3D printing with aluminum alloys, such as selective laser melting (SLM) and direct metal laser sintering (DMLS). These methods involve the fusion of powdered aluminum alloy and layering it to construct a three-dimensional object. Moreover, aluminum alloys possess numerous advantageous characteristics that render them suitable for 3D printing applications. These qualities encompass a superior strength-to-weight ratio, exceptional thermal conductivity, resistance against corrosion, and satisfactory machinability. |

|

|

| Stainless Steel | |

| Stainless steel is widely employed in 3D printing due to its superb characteristics. It possesses impressive strength, resistance to corrosion and heat, enabling it to suit rigorous applications. The remarkable ratio of strength to weight and ability to withstand extreme temperatures and corrosion render it an optimal material for industrial usage. |

Surface Finishing For 3D Printing

See What Our Customers

Say About Us

Rapid Estimate

Simply forward your CAD file and detailed specifications to our email, and you will receive a prompt quotation for 3D printed components in as little as 12 hours. With our refined production techniques, we are certain that we can offer you the most economically advantageous price for your 3D printing endeavor.

Quick Lead Time

The timeframe for completion is contingent upon various factors such as the overall dimensions, intricacy of the design, and your selection of 3D printing methodology. Nevertheless, Machininig-CNC prides itself on its ability to produce results swiftly, with a lead time as rapid as 4 days.

Superior Quality

To ensure that the 3D prints align with the specific needs of your application, we offer RoHS material certifications along with detailed dimensional inspection reports for every order placed. These reports are provided upon request, guaranteeing the high quality and suitability of our 3D prints.

At Machining-CNC we manufacture components for customers across a wide range of industries.

We offer 3D-printing services for: