CNC Milling Service

- Over 65 universal and complete Materials

- ±0.005mm strict Tolerance

- Lead times from 7 to 10 days

- Custom styles and finishes

- More than 650mm processing path

What is CNC Milling?

CNC milling is a precision-based manufacturing technique utilizing computer-controlled machinery to subtract material from a workpiece. This method employs a rotating cutting tool to carve out specific shapes from solid material blocks.

Milling machines excel in precision and can fabricate intricate geometries. Moreover, they can be programmed to yield numerous identical components, rendering milling an economically efficient manufacturing solution.

Why choose Machining-CNC’s CNC milled service?

Machining-CNC provides comprehensive milling solutions, catering to your needs, whether it's a single component, a small batch of prototypes, or large-scale mass production parts.

| Part size limitations | Metric units | lmperial units |

|---|---|---|

| Maximum Part Size | 3800×1300×500 mm | 149.6×51.8×19.7 in. |

| Minimum Part Size | 4×4 mm | 0.1×0.1 in. |

| Minimum Feature Size | Φ 0.40 mm | Φ 0.016 in. |

CNC Milling General Tolerances

With our precise CNC machining capabilities, Machining-CNC stands as your perfect collaborator in the production of accurate prototypes and parts. Our CNC machining adheres to ISO 2768-f standards for metals and ISO 2768-m standards for plastics, guaranteeing accuracy and quality. Moreover, we are fully capable of meeting any specific tolerances you may require, provided that you clearly outline your specifications on the drawing.

| Type | Tolerance |

|---|---|

| Linear Dimension | +/-0.01 mm |

| +/-0.0004 in. | |

| Hole Diameters | +/-0.02 mm |

| (Not Reamed) | +/-0.0008 in. |

| Shaft Diameters | +/-0.02 mm |

| +/-0.0008 in. |

CNC Milling Design Principles

Machining-CNC's CNC expert machinists have created the perfect specifications for the production of precise parts. The table lists the most effective methods for manufacturing and outlines any technical limitations which must be considered when producing.

| Standard | CNC Turning |

|---|---|

| Threads and Tapped Holes | Diameter:Φ1.5-5 mm, depth: 3xdiameter |

| Diameter: Φ 5 mm or more.depth: 4-6xdiameter | |

| Machining-CNC can produce threads of any specification and size required by our customers. | |

| Text | Minimum width of 0.5 mm, depth of 0.1 mm |

| Machining-CNC can use CNC engraving or laser carving to create standard text based on customers' requirements. |

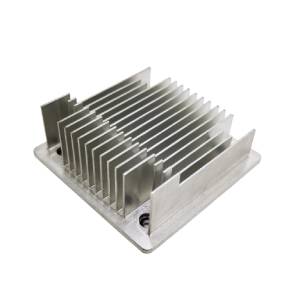

Metals

|

|

| Aluminum | |

| Aluminum alloys have a high strength-to-weight ratios, high electrical and thermal conductivity, low density, and natural resistance to corrosion. They can be anodized using a variety of techniques. |

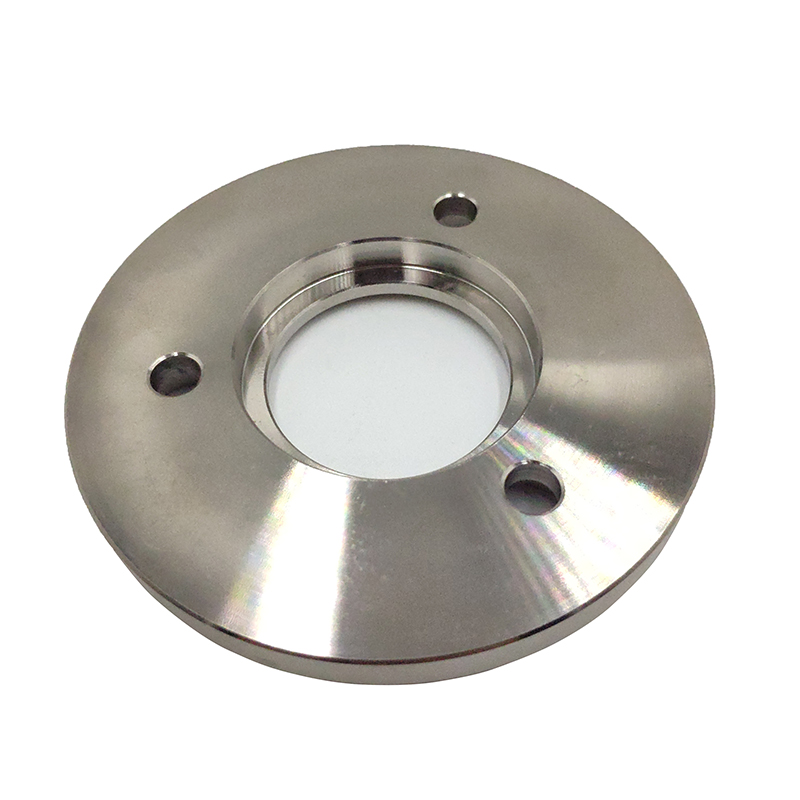

|

|

| Stainless Steel | |

| The stainless steel alloys are characterized by their excellent strength, ductility, corrosion and wear resistance. They can be easily joined and machined as well as polished. |

|

|

| Alloy steel | |

| Alloy steels incorporate additional alloying elements aside from carbon, leading to enhanced qualities such as increased hardness, toughness, fatigue resistance, and wear resistance. |

|

|

| Brass | |

| Brass displays outstanding easiness to machine, favorable ratio of strength to weight, resistance to corrosion, and proficient conduction of electricity and heat. |

|

|

| Copper | |

| Copper, a remarkably malleable metal, finds utility in various applications determined by its mechanical characteristics. It exhibits commendable durability, hardness, exceptional thermal and heat conduction abilities, and corrosion resistance. As a result, it has become a highly sought-after material highly regarded for both its practical functionality and its aesthetic appeal. Furthermore, copper possesses the versatility to be alloyed, thereby enhancing its mechanical attributes. |

|

|

| Titanium | |

| Titanium possesses a variety of material characteristics that designate it as the optimal metal for challenging applications. These traits encompass exceptional resilience against corrosion, chemicals, and extreme temperatures, as well as an exceptional ratio of strength to weight. |

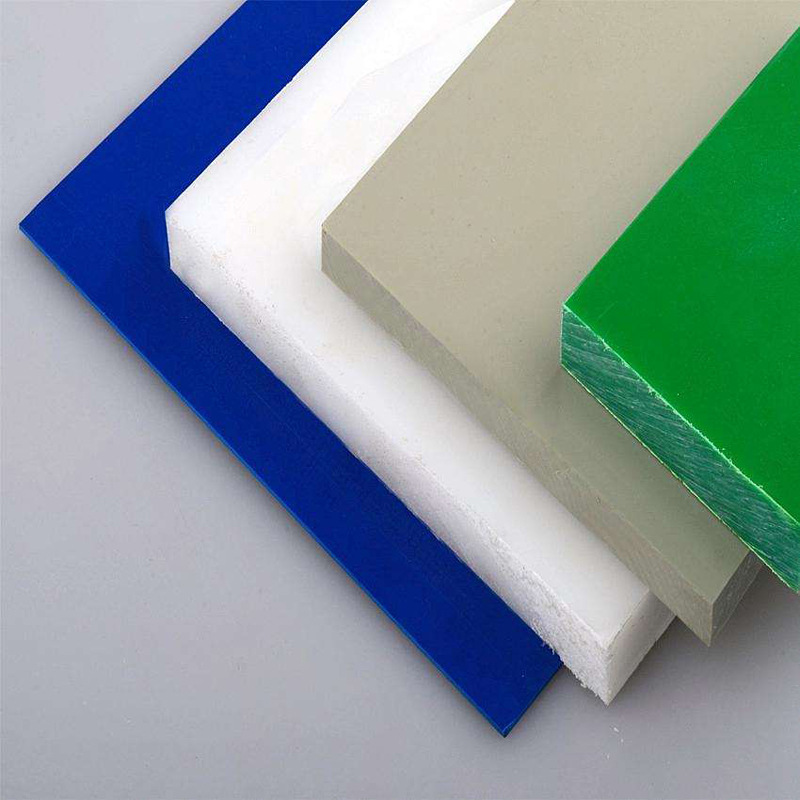

Plastics

|

| ABS |

| ABS, a frequently used thermoplastic, displays favorable mechanical characteristics, outstanding impact resilience, reliable heat tolerance, and commendable machinability. |

|

| FR4 |

| FR4, boasting excellent mechanical strength, superior electrical insulation, and superior machinability, is the ideal choice for electronic applications. |

|

| HDPE |

| HDPE exhibits outstanding resilience to impact, remarkable strength, and impressive machinability, making it well-suited for the production of resilient and sturdy machine components. |

|

| PE |

| PE is characterized by its remarkable impact resistance, exceptional ductility, and minimal friction, which render it an ideal choice for fabricating wear-resistant parts using machining techniques. |

|

| PA6 (Nylon) |

| In machining applications where parts undergo significant mechanical stress, PA6 proves to be an excellent choice due to its combination of high strength, wear resistance, and elasticity.When it comes to machining components that experience substantial mechanical stress, PA6 stands out as an exceptional material option due to its impressive strength, resistance to wear, and elasticity. |

|

| PA66 (Nylon) |

| PA66 displays favorable characteristics like high rigidity, hardness, wear resistance, and thermal dimensional stability. Furthermore, it showcases exceptional wear resistance, low friction, and excellent temperature, chemical, and impact resistance. Nevertheless, caution must be exercised during the processing of PA66 due to its propensity to absorb moisture, which can impact its dimensional stability. |

|

| PC (Polycarbonate) |

| PC, a thermoplastic material, possesses remarkable resilience, exceptional resistance to impacts, and ease of machining. Additionally, it has the capability to exhibit optical transparency. |

|

| PEEK |

| PEEK is characterized by its impressive strength, outstanding ability to withstand high temperatures, and excellent machinability — making it an ideal choice for various high-performance applications. PEEK offers exceptional strength, remarkable thermal resistance, and superior machinability, making it perfectly suited for demanding high-performance uses. |

|

| PMMA |

| PMMA provides remarkable light transmission, impressive mechanical strength, and impeccable machinability, making it a perfect material for optical and aesthetic applications. PMMA exhibits exceptional light transmission, superior strength, and excellent machinability, making it an ideal choice for optical and aesthetic purposes. |

|

| POM (Delrin/Acetal) |

| Precision parts that seek elevated rigidity, minimal friction, and outstanding dimensional stability benefit from the usage of POM, an engineering thermoplastic. |

|

| PP |

| With exceptional fatigue resistance, excellent chemical resistance, and impressive elasticity, PP is perfectly suited for fabricating machined parts that are lightweight and flexible. |

|

| PP5 |

| PPS exhibits superb resistance to chemicals, possesses remarkable strength, and demonstrates exceptional machinability; making it an optimal choice for the production of high-performance components. |

|

| PVC |

| Among plastics, PVC stands as the third most widely employed, boasting well-balanced mechanical characteristics, outstanding resistance to chemicals and weather conditions, and notable toughness. |

Others Materials

|

| Carbon Fiber |

| When it comes to machining, carbon fiber, also known as graphite fiber, emerges as a top contender due to its remarkable strength and lightweight nature. Outperforming steel with its five-fold strength and double the stiffness, carbon fiber is a sought-after material in the machining industry. |

|

| Wood |

| Natural aesthetic appeal: Wood offers a warm and visually pleasing appearance, adding a natural charm to products. Versatility: Wood can be easily shaped and carved using CNC machines, allowing for intricate designs and customization. Sustainability: Wood is a renewable resource, making it an environmentally-friendly choice for CNC processed products. Cost-effectiveness: Compared to other raw materials, wood can be relatively affordable, making it a cost-effective option for production. Durability: With proper maintenance and treatment, wood can have good resistance to wear, tear, and impact. |

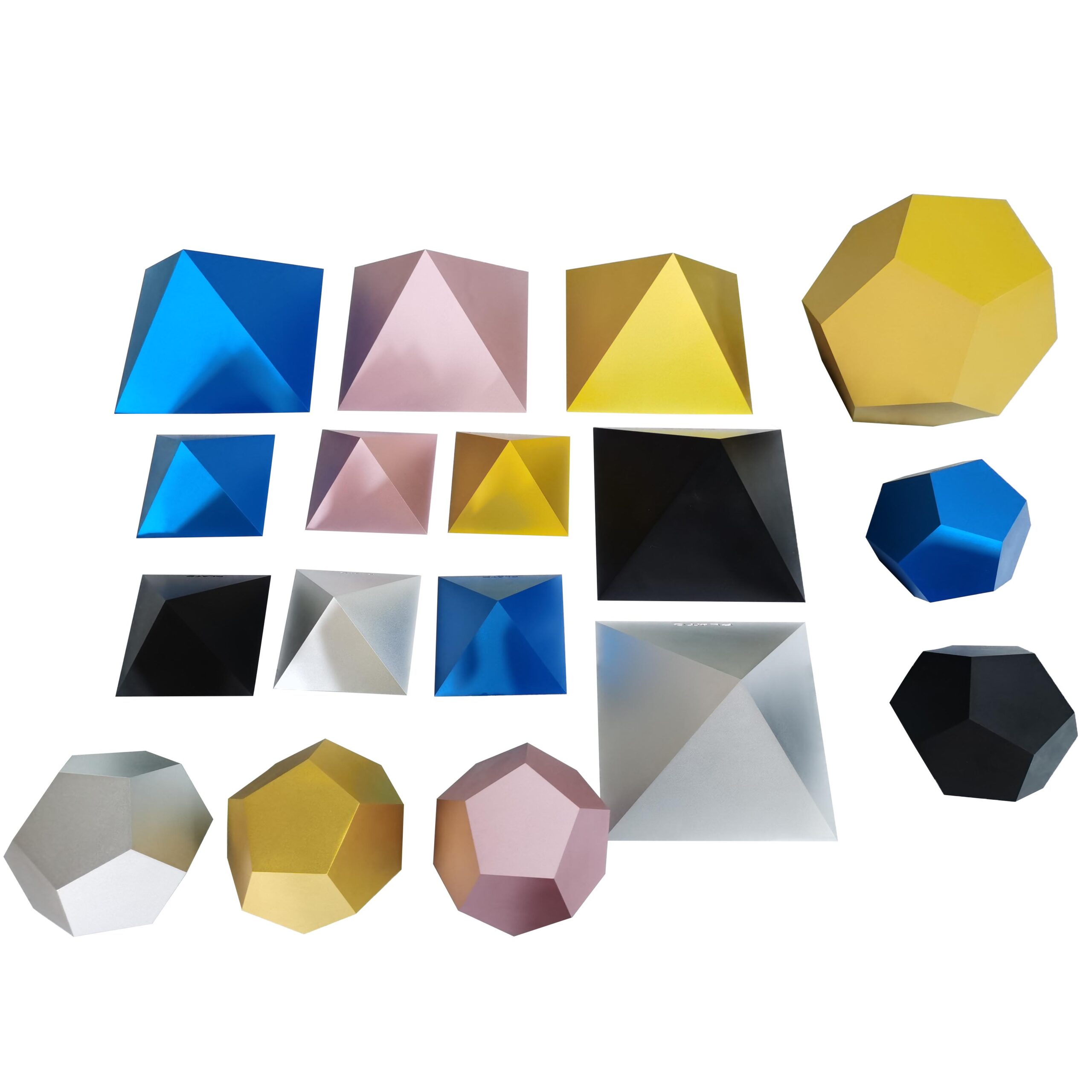

Surface Finish Choices For CNC Milled Parts

Machining-CNC offers a wide range of surface finishes to enhance the surface quality of CNC milled components to meet the needs of more customers. Surface treatments change appearance, surface roughness and chemical resistance.

Why Order CNC Milled Parts From Machining-CNC?

Applications Of CNC Milling

Automobiles

In the manufacturing of engine components, Machining-CNC utilizes CNC milling to craft essential parts like cylinder heads, engine blocks, and crankshafts with exceptional precision and stringent tolerances.

Primarily in the realm of mold and tool fabrication and for custom prototyping, automotive manufacturers employ CNC milling to swiftly create prototypes and evaluate new vehicle designs. This iterative process enables adjustments and enhancements before transitioning to large-scale production.

Unmanned Aerial Vehicle

Machining-CNC specializes in CNC milling, a widely utilized method in the production and fabrication of parts for unmanned aerial vehicles (UAVs). CNC milling involves the computer-controlled removal of material from a workpiece to achieve the desired shape. Within the drone industry, CNC milling serves as a critical technique for manufacturing components like frames, brackets, and propeller mounts using materials including aluminum, carbon fiber, and plastic.

Electronic

In PCB prototyping, Machining-CNC employs CNC milling techniques to fabricate printed circuit board (PCB) prototypes with precision. This involves precise engraving of copper traces and hole drilling, enabling engineers to validate and enhance their designs before transitioning to large-scale production.

Furthermore, CNC milling serves a diverse range of applications, including the customization of distinctive casings, the intricate production of connectors, and the crafting of front panels and displays that demand meticulous shear engraving.

Medical

CNC turning is employed by the industry of medical equipment to produce precision components made of a cylindrical design for various medical devices such as implants, surgical instruments, and prosthetics.

Applications span from crafting microscopic elements for gastrointestinal endoscopy equipment to fabricating custom tools and fixtures vital for medical research and testing. Furthermore, CNC milling finds pivotal use in the creation of surgical guides, facilitating precise instrument positioning during surgery, thereby enhancing precision while minimizing invasiveness.

Aerospace

In the aerospace sector, Machining-CNC employs CNC milling to manufacture vital components for aircraft engines, including turbine blades, combustion chambers, and compressor parts. This meticulous process ensures outstanding precision and longevity.

Furthermore, CNC milling is instrumental in shaping structural elements like wing spars, frames, and bulkheads within aircraft, guaranteeing the structural soundness and resilience of these aerospace vehicles.

FAQ

Through the controlled movement of cutting tools, our CNC milling machines precisely sculpt and refine the workpiece to the desired dimensions and shape, eliminating any excess material in the process.The CAD file acts as an essential blueprint, enabling our CNC machines to operate with utmost precision. Guided by the toolpath, the cutting tools traverse the workpiece, selectively removing material in accordance with the specified instructions.

This meticulous approach ensures accuracy and consistency, resulting in finely crafted components that meet the exact specifications outlined in the CAD file.By utilizing CNC milling, we deliver exceptional results, transforming raw materials into intricately shaped and precisely machined components that cater to our clients' specific requirements.

CNC milling is the use of an instrument that rotates and is moved across a workpiece to take material off its surface. Milling processes can create an array of geometries, such as smooth and inclined surfaces as well as grooves, slots and slots.

CNC turning on contrary, spins the workpiece, while the cutting tool stays stationary, forming the material to what you want. It is used primarily to make cylindrical parts. It is ideal for making parts that are symmetrical, such as shafts, pins and bushings.

Moreover, two additional rotational movements enable the tool to access even more angles and surfaces of the material being worked on. This amalgamation of linear and rotational movements defines the "5-axis" nomenclature.By harnessing these extra movements, our 5-axis CNC machines have the ability to manufacture complex shapes and intricate designs that are otherwise challenging or unattainable with traditional 3-axis machines, limited to moving solely along the X, Y, and Z directions without rotation.

This advanced capability not only enhances production speed but also ensures superior precision and facilitates the realization of more sophisticated parts in our manufacturing processes.