Industrial

Machinery

Precision in Every Part,

Powering Industry

- Effortless Quoting, Detailed DFM Analysis

- Vast Tech and Material Options

- Global Speed and Trusted Reliability

Our CNC Machining Service in

Industrial Machinery

In the dynamic landscape of industrial machinery, Anebon emerges as a distinctive and influential player, contributing significantly to the evolution and optimization of manufacturing processes. Anebon's journey through the realm of precision engineering and cutting-edge solutions has established it as a formidable force in the industrial machinery sector.

With a commitment to excellence woven into its DNA, Anebon stands as a beacon of reliability in an industry where precision and efficiency are paramount. Its journey is one of continuous exploration, where each challenge is met with ingenuity and each project serves as a testament to its unwavering dedication to enhancing the world of industrial machinery.

Geared Up for Launch

In the realm of OEM aerospace parts, where the pursuit of excellence requires the tightest tolerances and the most advanced precision machines, Anebon stands tall as the premier machine shop for the job. From concept to reality, we transform your aerospace visions into meticulously crafted components that soar to new heights of performance and reliability.

Industrial Machinery?

Industrial Machinery?

CNC machining is a cornerstone of Anebon's operations in industrial machinery. This technology enables the creation of intricate parts and components that are crucial for the optimal functioning of machinery. Some examples of products that can be manufactured using CNC machining in industrial machinery include:

Gears and Shafts

Helical Gear, Bevel Gear, Precision Drive Shaft

These components are essential for transmitting motion and power within industrial machinery, ensuring smooth and efficient operations.

Custom Housings and Enclosures

Control panels, sensors, motors, communication devices

These enclosures ensure protection from environmental factors, safeguarding sensitive electronics and enhancing machinery performance.

Complex Mechanical Assemblies

Gearbox assemblies and robot arms

CNC machining's precision enhances the reliability and functionality of diverse industrial machinery components, ensuring seamless operations across industries.

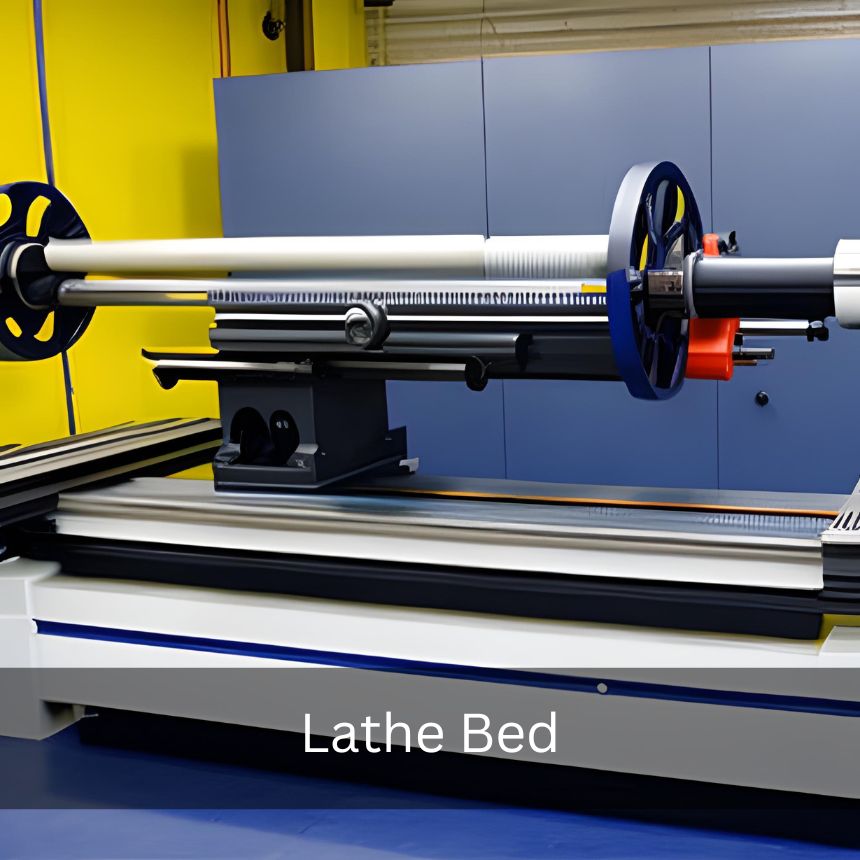

Critical Structural Components

Base Frame, Column Support, Machine Bed

CNC machining shapes robust structural components like frames and supports, ensuring stable and enduring performance across manufacturing, energy, and transportation.

Anebon's role in the industrial machinery sector encompasses a range of services and contributions. The company specializes in the design, manufacturing, and supply of critical components, subassemblies, and complete machinery systems. Their skilled engineers and technicians collaborate closely with clients to understand specific requirements, ensuring that the final product aligns seamlessly with operational needs.

One of Anebon's standout capabilities is its proficiency in CNC machining. This advanced manufacturing technique allows the company to craft intricate and precise parts with exceptional accuracy. Anebon leverages CNC machining to produce a diverse array of components used in industrial machinery, which brings us to the next point.

Anebon's profound involvement in the industrial machinery sector is characterized by an intricate tapestry of expertise in precision engineering, an adept embrace of cutting-edge technologies like CNC machining, and an unwavering commitment to delivering solutions tailored with precision to the specific demands of diverse industries. This holistic approach not only underscores Anebon's mastery in crafting components and systems that seamlessly integrate into industrial machinery but also showcases its ability to synergize innovation with practicality. With an illustrious history of setting benchmarks in excellence and pioneering innovation, Anebon remains at the forefront of revolutionizing industrial processes, enhancing the efficacy, reliability, and overall performance of machinery in varied sectors.

Anebon's enduring presence as a catalyst for industrial advancement is a testament to its unwavering pursuit of excellence and its ability to translate innovation into tangible results. By consistently pushing boundaries, Anebon has entrenched itself as an indispensable partner across industries, diligently refining the interplay between precision engineering, advanced technologies, and custom solutions. In a landscape where efficiency and reliability are paramount, Anebon's contributions stand as a beacon of transformative potential, serving as a cornerstone for elevating industrial machinery to unprecedented heights of productivity and dependability.