Robotics &

Automation

Efficiency and Innovation

Shaping CNC Machining's Future

- Crafting custom parts of diverse complexities

- Ideal for all manufacturing scales

- Swift, reliable options worldwide

Our CNC Machining Service in

Robotics & Automation

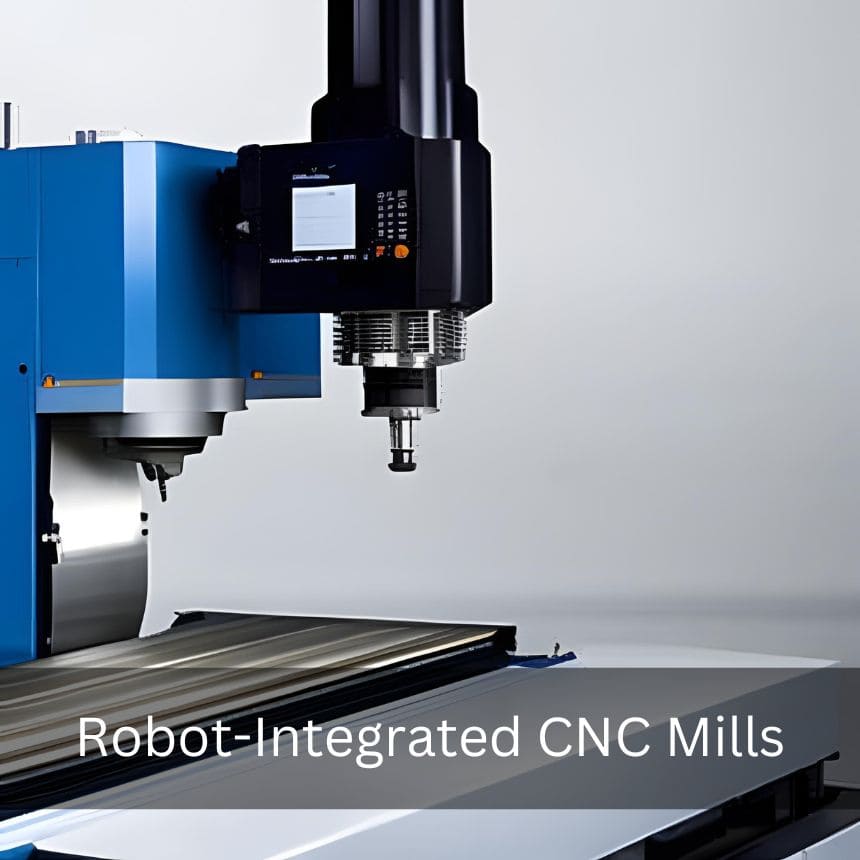

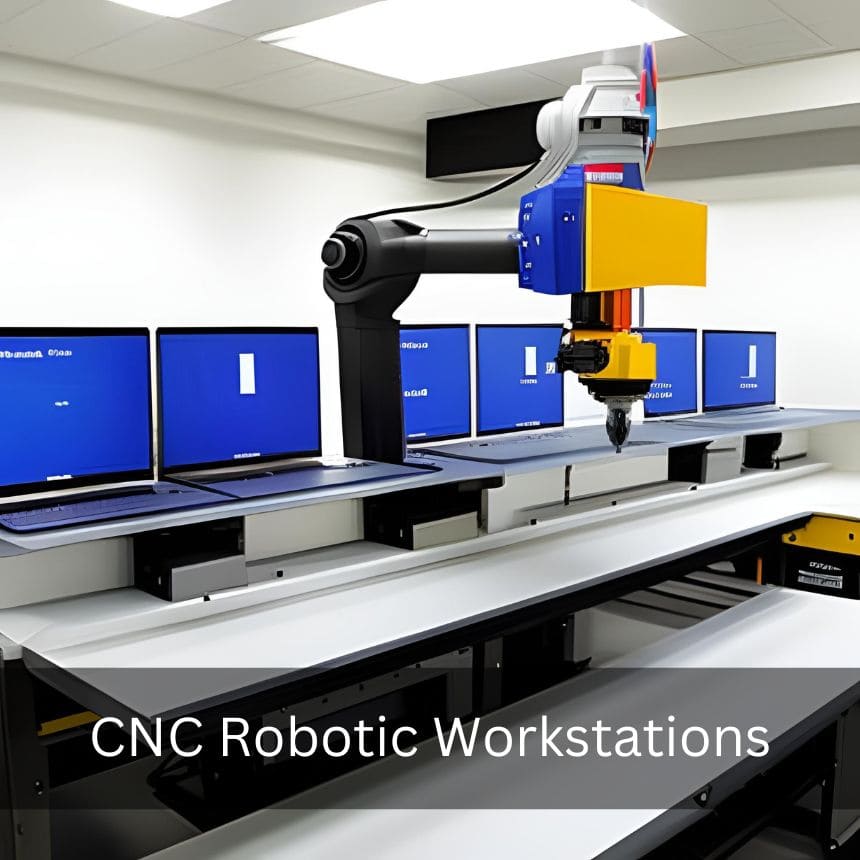

In the ever-evolving landscape of technology, Robotics & Automation emerge as the driving forces revolutionizing industries across the globe. Machining-CNC, a visionary entity renowned for its precision engineering prowess, has seamlessly integrated itself into this transformative realm.

Machining-CNC's Role in Robotics & Automation

Machining-CNC's involvement in the Robotics & Automation industry is a testament to its dedication to advancing technological frontiers. Leveraging its expertise, the company crafts solutions that redefine the way industries operate.

From collaborative robots streamlining manufacturing processes to automated systems enhancing efficiency, Machining-CNC's impact resonates through various sectors. The fusion of CNC machining and robotics engineering brings forth a harmonious convergence that not only pushes the boundaries of automation but also elevates the precision and reliability of robotics components.

Medical Parts?

CNC machining can be used to produce various robotics and automation parts due to its precision, versatility, and ability to work with different materials. Some parts that can be made using CNC machining include:

Robot Arms

Arm Joints, End Effectors, Actuator Mounts

Intricate robotic arms, meticulously crafted through CNC machining, form the backbone of automated processes

Grippers

Precision Grippers, Modular Gripper Fingers, Adaptive Grips

CNC-machined grippers enable precise handling and manipulation of objects in various industrial settings

Sensor Housings

Enclosure Caps, Probe Casing, Sensor Cover Plates

These housings provide protection to sensitive sensors used in applications like autonomous vehicles, agricultural robotics, and smart factories

Control Panels

Keypad Assemblies, Control Enclosures, Panel Bezels

These housings provide protection to sensitive sensors used in applications like autonomous vehicles, agricultural robotics, and smart factories

By utilizing CNC machining to produce these robotics and automation parts, manufacturers can achieve superior accuracy and consistency, ensuring that each component meets the rigorous demands of applications. The ability to work with various materials, including metals and composites, makes CNC machining a valuable technology in the robotics and automation industry for creating durable and reliable parts.

Robotics & Automation

CNC machining brings unparalleled advantages to Robotics & Automation:

Machining-CNC's Robotics Revolution

Machining-CNC's pioneering spirit is at the vanguard of catalyzing transformation across industries through its Robotics & Automation solutions. By embracing the latest advancements and pushing the boundaries of what's possible, Machining-CNC is actively shaping the landscape of various sectors. From manufacturing to healthcare and beyond, the company's innovative solutions introduce a new era of efficiency, precision, and adaptability.

Whether it's reimagining assembly lines with collaborative robots or enabling autonomous vehicles to navigate our roads, Machining-CNC's Robotics Revolution stands as a testament to its commitment to engineering excellence and the profound impact it has on making industries more streamlined, sustainable, and future-ready.

Within Machining-CNC's comprehensive approach to Robotics & Automation, CNC machining emerges as the pivotal force driving excellence in component fabrication. The symbiotic relationship between CNC machining and robotics engineering results in components that embody the highest standards of accuracy and durability.

These CNC-machined parts, whether they are intricate sensor housings or robust robot arms, represent the nexus of innovation and craftsmanship. By creating components that meet the stringent demands of robotic applications, CNC machining ensures that the heart of automated systems beats with reliability, precision, and a commitment to delivering results that redefine the very essence of robotic excellence.

Let's Start a New Project Now!

As Robotics & Automation continue to reshape industries, Machining-CNC's dedication to precision engineering, fueled by CNC machining prowess, paves the way for a world where machines seamlessly collaborate with human ingenuity. With an unwavering focus on innovation and quality, Machining-CNC drives the evolution of robotics, ushering in a future where the limits of automation are bound only by imagination.