Medical

Accuracy Healing,

Crafted by CNC Mastery

- Unlocking Intricate Designs & Exquisite Surfaces

- Get Immediate Quotes with Detailed DFM Insights

- Expert Certifications & Impeccable Quality Records

Our CNC Machining Service in

Medical Industry

Welcome to Machining-CNC Medical Solutions, where precision, safety, and innovation converge to revolutionize the landscape of medical manufacturing. In a world where medical equipment, implants, and components play a crucial role in delivering advanced healthcare solutions, we are dedicated to crafting high-quality, dependable, and safe products that can improve the lives of patients and medical professionals alike.

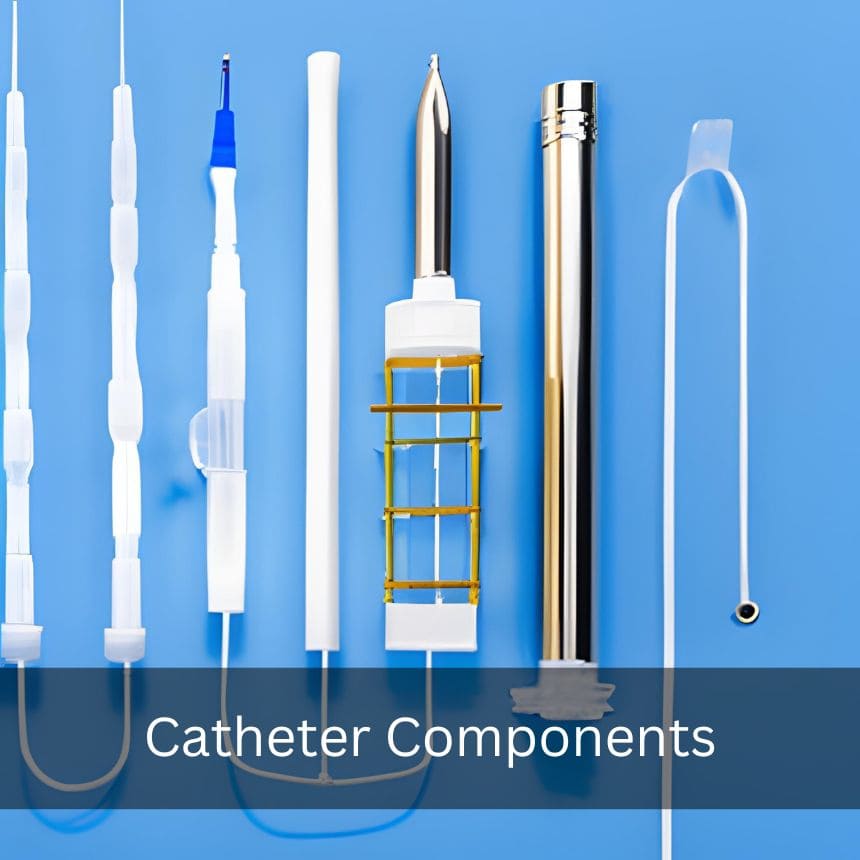

CNC machining can be utilized to produce a wide range of medical parts due to its precision, accuracy, and ability to work with various medical-grade materials. Some medical parts that can be made using CNC machining include:

Surgical Instruments

Bone Drill, Trocar, Ophthalmic Forceps

- Surgical precision with high accuracy

- Frictionless surfaces for smooth interaction

- Intricate, precise designs achieved

Orthopedic Implants

Plates, screws and rods integral

- Accurate alignment ensured

- Body-safe composition

- Tailored to patients

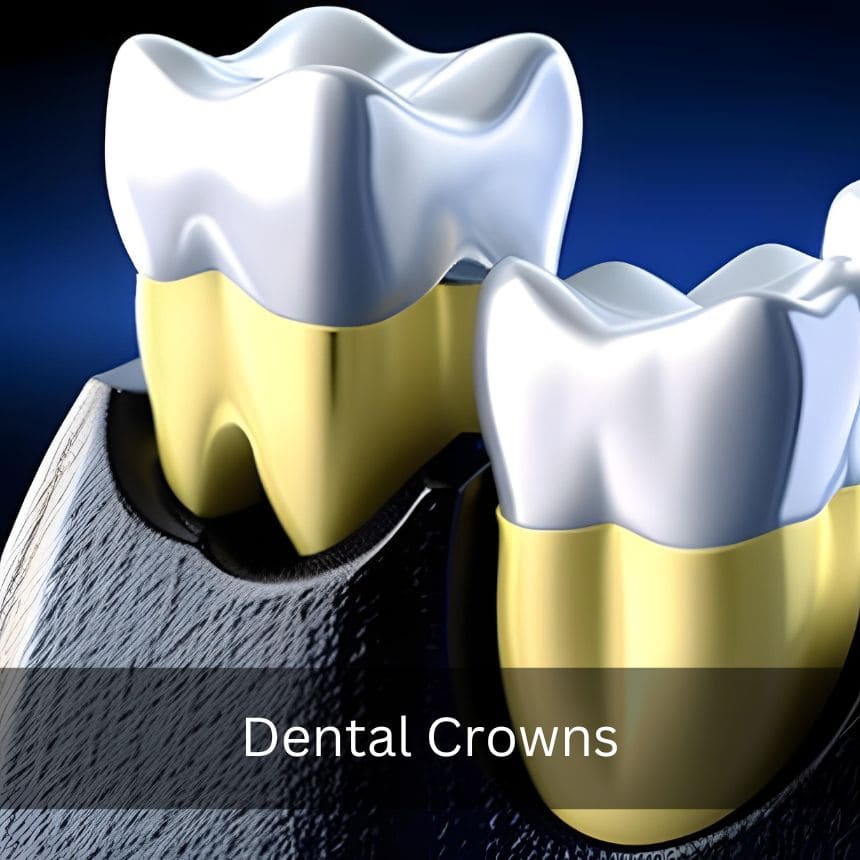

Dental Components

Dental implant abutments, crowns, bridges

- High tolerance requirements

- Intricate shapes achievable

- Safe oral use materials

Prosthetics

Custom Limbs, Dental Restorations, Cranial Implants

- Achieves high accuracy and tight tolerances

- Tailored to individual patient needs

- Uses safe materials

Medical Parts

CNC machining offers several advantages for manufacturing medical parts:

In summary, CNC machining provides precision, customization, material versatility, and cost-effectiveness, making it an invaluable manufacturing method for medical parts. These advantages contribute to the production of reliable, patient-specific, and high-performance medical components, enhancing medical treatment and improving patient care.

At Machining-CNC Medical Solutions, we understand that the medical industry is constantly evolving, with unique challenges and specialized requirements arising in various medical fields. Under this subheading, we highlight our ability to provide customized solutions that cater to the specific needs of medical innovators and healthcare professionals.

Our team of skilled engineers and medical experts collaborates closely with clients to gain in-depth insights into their projects and medical applications. By understanding the nuances of their requirements, we develop tailored solutions that meet precise specifications and contribute to groundbreaking medical advancements.

Whether it's crafting specialized components for cutting-edge surgical tools or developing implants that adhere to unique anatomical considerations, our commitment to customization ensures that our clients receive products that align perfectly with their medical innovations.

Advanced Manufacturing

Precision and quality are the cornerstones of success in the medical industry, where even the smallest component can make a significant difference in patient outcomes. Under this subheading, we delve into our advanced manufacturing capabilities, which allow us to uphold the highest levels of precision and quality in every product we create. Machining-CNC employs state-of-the-art technologies and modern manufacturing processes that ensure consistency and accuracy in our medical components. From cutting-edge CNC machining to advanced inspection and testing methods, we leave no room for compromise when it comes to safety and reliability.

Our skilled workforce, coupled with our ISO9001:2015 certified quality management system, guarantees that each product undergoes rigorous quality assurance procedures at every stage of production. As a result, our clients can trust that the medical parts and products they receive from Machining-CNC are of unparalleled precision and adhere to the most stringent quality standards.

Let's Start a New Project Now!

Machining-CNC Medical Solutions is a proud contributor to advancing healthcare through cutting-edge solutions and precision parts. With ISO9001:2015 certification, we're dedicated to quality and safety. Guided by innovation, we're shaping healthcare's future and empowering professionals. Reach out to us today to collaborate in elevating patient care and pushing medical boundaries. Let's create a healthier, happier tomorrow together.