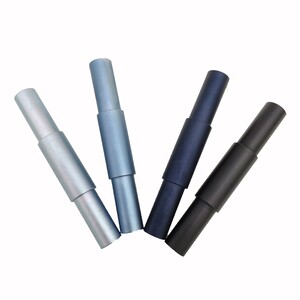

CNC Turning Service

Precision in Every Revolution:

Our CNC Turning Service Sets the Standard.

- Over 65 universal and complete Materials

- Lead times from 7 to 10 days

- Custom styles and finishes

What is CNC Turning ?

CNC turning is the method of removing materials from a rotating workpiece through the linear path of tools in the CNC lathe. From a basic view, the primary components that are involved in this process are the spindle rotating that is where your work piece is held as well as the cutting device that is placed on an turntable.

Our CNC turning center, Machining-CNC has long-term accumulated expertise and the ability to create intricate and high-precision dimension components using CNC lathes providing top-quality plastic, metal and even wood CNCs for rapid prototyping and small batches of production Turned components.

Why choose Machining-CNC's CNC turned service?

| Part size limitations | Metric units | lmperial units |

|---|---|---|

| Maximum Part Size | 180×450 mm | 7.1×17.7 in. |

| Minimum Part Size | 2×2 mm | 0.079×0.079 in. |

| Minimum Feature Size | Φ 0.40 mm | Φ 0.016 in. |

CNC Turning General Tolerances

With our precise CNC machining capabilities, Machining-CNC stands as your perfect collaborator in the production of accurate prototypes and parts. Our CNC machining adheres to ISO 2768-f standards for metals and ISO 2768-m standards for plastics, guaranteeing accuracy and quality. Moreover, we are fully capable of meeting any specific tolerances you may require, provided that you clearly outline your specifications on the drawing.

| Type | Tolerance |

|---|---|

| Linear Dimension | +/-0.01 mm |

| +/-0.0004 in. | |

| Hole Diameters | +/-0.02 mm |

| (Not Reamed) | +/-0.0008 in. |

| Shaft Diameters | +/-0.02 mm |

| +/-0.0008 in. |

CNC Turning Design Principles

Machining-CNC's CNC expert machinists have created the perfect specifications for the production of precise parts. The table lists the most effective methods for manufacturing and outlines any technical limitations which must be considered when producing.

| Standard | CNC Turning |

|---|---|

| Threads and Tapped Holes | Diameter:Φ1.5-5 mm, depth: 3xdiameter |

| Diameter: Φ 5 mm or more.depth: 46xdiameter | |

| Machining-CNC can produce threads of any specification and size required by our customers. | |

| Text | Machining-CNC can use laser marking to create standard text for CNC turned parts. |

| Machining-CNC can use CNC engraving or laser carving to create standard text based on customers' requirements. |

Metals

|

|

| Aluminum | |

| Aluminum alloys have a high strength-to-weight ratios, high electrical and thermal conductivity, low density, and natural resistance to corrosion. They can be anodized using a variety of techniques. |

|

|

| Stainless Steel | |

| The stainless steel alloys are characterized by their excellent strength, ductility, corrosion and wear resistance. They can be easily joined and machined as well as polished. |

|

|

| Alloy steel | |

| Alloy steels incorporate additional alloying elements aside from carbon, leading to enhanced qualities such as increased hardness, toughness, fatigue resistance, and wear resistance. |

|

|

| Brass | |

| Brass displays outstanding easiness to machine, favorable ratio of strength to weight, resistance to corrosion, and proficient conduction of electricity and heat. |

|

|

| Copper | |

| Copper, a remarkably malleable metal, finds utility in various applications determined by its mechanical characteristics. It exhibits commendable durability, hardness, exceptional thermal and heat conduction abilities, and corrosion resistance. As a result, it has become a highly sought-after material highly regarded for both its practical functionality and its aesthetic appeal. Furthermore, copper possesses the versatility to be alloyed, thereby enhancing its mechanical attributes. |

|

|

| Titanium | |

| Titanium possesses a variety of material characteristics that designate it as the optimal metal for challenging applications. These traits encompass exceptional resilience against corrosion, chemicals, and extreme temperatures, as well as an exceptional ratio of strength to weight. |

Plastics

|

| ABS |

| ABS, a frequently used thermoplastic, displays favorable mechanical characteristics, outstanding impact resilience, reliable heat tolerance, and commendable machinability. |

|

| FR4 |

| FR4, boasting excellent mechanical strength, superior electrical insulation, and superior machinability, is the ideal choice for electronic applications. |

|

| HDPE |

| HDPE exhibits outstanding resilience to impact, remarkable strength, and impressive machinability, making it well-suited for the production of resilient and sturdy machine components. |

|

| PE |

| PE is characterized by its remarkable impact resistance, exceptional ductility, and minimal friction, which render it an ideal choice for fabricating wear-resistant parts using machining techniques. |

|

| PA6 (Nylon) |

| In machining applications where parts undergo significant mechanical stress, PA6 proves to be an excellent choice due to its combination of high strength, wear resistance, and elasticity.When it comes to machining components that experience substantial mechanical stress, PA6 stands out as an exceptional material option due to its impressive strength, resistance to wear, and elasticity. |

|

| PA66 (Nylon) |

| PA66 displays favorable characteristics like high rigidity, hardness, wear resistance, and thermal dimensional stability. Furthermore, it showcases exceptional wear resistance, low friction, and excellent temperature, chemical, and impact resistance. Nevertheless, caution must be exercised during the processing of PA66 due to its propensity to absorb moisture, which can impact its dimensional stability. |

|

| PC (Polycarbonate) |

| PC, a thermoplastic material, possesses remarkable resilience, exceptional resistance to impacts, and ease of machining. Additionally, it has the capability to exhibit optical transparency. |

|

| PEEK |

| PEEK is characterized by its impressive strength, outstanding ability to withstand high temperatures, and excellent machinability — making it an ideal choice for various high-performance applications. PEEK offers exceptional strength, remarkable thermal resistance, and superior machinability, making it perfectly suited for demanding high-performance uses. |

|

| PMMA |

| PMMA provides remarkable light transmission, impressive mechanical strength, and impeccable machinability, making it a perfect material for optical and aesthetic applications. PMMA exhibits exceptional light transmission, superior strength, and excellent machinability, making it an ideal choice for optical and aesthetic purposes. |

|

| POM (Delrin/Acetal) |

| Precision parts that seek elevated rigidity, minimal friction, and outstanding dimensional stability benefit from the usage of POM, an engineering thermoplastic. |

|

| PP |

| With exceptional fatigue resistance, excellent chemical resistance, and impressive elasticity, PP is perfectly suited for fabricating machined parts that are lightweight and flexible. |

|

| PP5 |

| PPS exhibits superb resistance to chemicals, possesses remarkable strength, and demonstrates exceptional machinability; making it an optimal choice for the production of high-performance components. |

|

| PVC |

| Among plastics, PVC stands as the third most widely employed, boasting well-balanced mechanical characteristics, outstanding resistance to chemicals and weather conditions, and notable toughness. |

Others Materials

|

| Carbon Fiber |

| When it comes to machining, carbon fiber, also known as graphite fiber, emerges as a top contender due to its remarkable strength and lightweight nature. Outperforming steel with its five-fold strength and double the stiffness, carbon fiber is a sought-after material in the machining industry. |

|

| Wood |

| Natural aesthetic appeal: Wood offers a warm and visually pleasing appearance, adding a natural charm to products. Versatility: Wood can be easily shaped and carved using CNC machines, allowing for intricate designs and customization. Sustainability: Wood is a renewable resource, making it an environmentally-friendly choice for CNC processed products. Cost-effectiveness: Compared to other raw materials, wood can be relatively affordable, making it a cost-effective option for production. Durability: With proper maintenance and treatment, wood can have good resistance to wear, tear, and impact. |

Surface Finish Choices For CNC Turned Parts

Machining-CNC's CNC expert machinists have created the perfect specifications for the production of precise parts. The table lists the most effective methods for manufacturing and outlines any technical limitations which must be considered when producing.

Our company is an ISO9001 certified business. We have worked with customers from a variety of industries, delivering rapid prototypes and high and low volume production orders for clients in many industries, all of that required us to create industrial components as well as turned metal products.

Industries include medical devices, aerospace, automobiles, industrial automation, machinery, ships, etc.

Applications Of CNC Turning

Automobiles

CNC lathes can be used for creating complex shapes and distinctive designs. They can make crankshafts that are customized for different engine configurations. It doesn't matter if it's a four-cylinder or six-cylinder V8 engine with high performance CNC turning is able to create crankshafts that satisfy certain specifications.

Industrial Automation

In the field of industrial automation the versatility of CNC lathes allows for efficient mass production of valve parts. Thanks to automation they are able to produce components with no need for constant human involvement. This improves productivity, lowers cost of labor and allows for continuous quality control.

Electronic

CNC lathes are utilized to make high-precision connector bodies and pins, as well as, most important connectors. CNC lathes guarantee consistent quality and high-precision. Computer-controlled processes guarantee that every connector is produced to precise tolerances, which guarantees a secure and precise connection.

Medical Devices

CNC turning is employed by the industry of medical equipment to produce precision components made of a cylindrical design for various medical devices such as implants, surgical instruments, and prosthetics.

Aerospace

CNC turning is used to create shafts for aerospace use. These shafts must be precisely machined in order to ensure that they meet the highest tolerance and quality requirements.

FAQ’S

CNC milling is the use of an instrument that rotates and is moved across a workpiece to take material off its surface. Milling processes can create an array of geometries, such as smooth and inclined surfaces as well as grooves, slots and slots.

CNC turning on contrary, spins the workpiece, while the cutting tool stays stationary, forming the material to what you want. It is used primarily to make cylindrical parts. It is ideal for making parts that are symmetrical, such as shafts, pins and bushings.

2. Speed Rough turning is usually done at higher speeds to eliminate materials quickly, while finishing turning is done at slower speeds to give more smooth surfaces with more precisely cut.

3. Tool Selection: Since rough turning requires a larger cut, it typically employs larger and stronger tool inserts. Finish turning however, on the other however, usually uses smaller and lighter tool inserts for better finish on the surface.

4. Cutting Path Rough turning generally follows a straight cutting path while finishing turning might employ a method called "light cuts" that involves the tool following a slight bent path.

- Advanced Precision: CNC lathes are able to achieve extraordinary degrees of precision, as well as precision, making them perfect for jobs which require precise tolerances. They are able to create intricate and complex parts with high-quality and consistency.

- Reliability: CNC lathes can replicate the same piece of work repeatedly without variations. This is vital in the aerospace industry or automotive. components need to meet the strictest quality standards.

- Flexibility: CNC lathes can be programmed to make a diverse assortment of parts, ranging from basic to extremely complicated geometries. They are able to handle a variety of types of materials, including metals plastics and composites.

- Effectiveness: CNC lathes operate continuously without needing breaks which reduces downtime and increases productivity. They can be run without supervision even at night, which saves time and costs for labor.

- Easy Prototyping: CNC lathes can quickly make prototypes and smaller batches of parts, which allow for quick design iterations and testing.

Disadvantages associated with CNC Lathe processing:

- Maintenance and downtime: CNC machines require regular maintenance and sudden breakdowns can cause costly downtime. Maintenance and repairs of CNC lathes can be costly.

- Complexity of Programming Programming complex: CNC programs for complicated parts can take a long time and require knowledge. Programming errors can cause costly errors.

- Limits of Flexibility: CNC lathes excel in precision, repetitive tasks but they're not as flexible to one-off and small-scale production runs, whereas manual machining could be more effective.

- Capital intensive: CNC lathes may require an investment in capital to purchase fixtures, tools and other accessories. This could further raise the cost of implementing this technology.

- Dimension Limitations: CNC lathes come in a variety of sizes, however very small or extremely large parts might require special equipment.